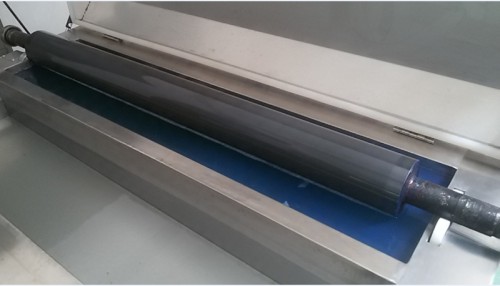

This kind of Ultrasonic Cleaner is designed just for Cleaning of Anilox Roller.

Ultrasonic Cleaner for Cleaning of Anilox Roller

Product Description

In flexographic printing, transmit a mount of printing ink on roller printing plate evenly will make net hole hindered by ink skin, paper coating, paper wool or other dirt, which will affect quality of printing and normal use of anilox roll, so it is essential to be cleaned timely, using ultrasonic cleaning is a common way. Rotating anilox roll while cleaning by ultrasonic, high frequency ultrasonic transducer in pool will start to vibrate, due to the vibration and micro bubbles close to body of roll for continuous rotation of body of roll and lash roll and ink residue in depth net-hole, which make residue swayed and separated from net hole continuously for cleaning.

► Specialty of ultrasonic in cleaning micro-hole

Although the kinds of anilox roll is divided into metal roll and ceramic roll, the micro net-hole is used for storing printing ink, as example of normal mesh roll 600L/ICH, the aperture of its net-hole is about 30 microns, generally speaking, normal cleaning tools won’t have such micro tools for cleaning net-hole; but diameter of water vacuole produced by ultrasonic is about two to five microns, there can come 6 to 15 water vacuole into single net-hole to impact bottom dirt physically for reaching purpose of completely clean, which is cannot compared by other cleaning methods. Currently, most of micro cleaning in the world uses ultrasonic cleaner and its application range is inclusive.

► Ultrasonic cleaning effect is more complete

The principle of ultrasonic cleaning is hundred of millions water vacuole which is produced by ultrasonic transducer and cannot be seen by naked eye, water vacuoles round mesh roll collectively and evenly, water vacuoles can come in and take dirt away whatever plane or depression point. The role cleaning solution is to activate dirt which attached on mesh roll and make its adsorption capability decreased.Being taken by water vacuole which produced by ultrasonic in a walk and reach the purpose of complete cleaning. Meanwhile, water vacuole produced by ultrasonic impacts and takes dirt away which is belong to physical function, but cleaning solution is to decrease adsorption capability of dirt which is belong to chemical function, like western medicine is a palliative treatment but TCM is the cure of the root cause, the combination of physical and chemical principles makes cleaning more complete and reasonable; This is its merit which is not available in other methods.

► Hard to damage roller

The pure physical strength of micro water vacuole which is produced by ultrasonic, its impact to laundered object is limited; Energy of impact is controlled by power and frequency of ultrasonic generator, the selected technical data is different with different cleaning object. Through controlling to decrease the damage to anilox roller at minimum degree during process of cleaning to.

► More convenient operation and environmentally-protected

Ultrasonic cleaning is a green and environmentally-protected method which can change electric energy into kinetic energy without dust and sewage, the only consumptive material is cleaning solution which can increase activity for dirt and make dirt taken easily, the whole cleaning method is very simple as pressing cleaning switch after putting aniloxl roll in the slot injected by cleaning solution; choose the cleaning solution which is suit with environmental protection for being emitted into sewer directly.

► The comparison with other cleaning methods

Although there are other cleaning methods in cleaning anilox roll: use caustic soda or alkali to heat up and clean, inject high pressure gas sand blasting or baking soda powder to clean directly and so forth, currently, use ultrasonic cleaner is much safer and has better effect. The comparison of three kinds of cleaning method is as follow:

1)The cleaning by baking soda powder or heating belong belongs to pure chemical function, the merits is cheap, but its is not suit with metal anilox roll for corruption; Though ceramic roller has a degree of anti-corrosive ability to alkali, metal base rod of anilox roll will tend to be accepted thermal expansion during process of heating, and make surface pottery and porcelain produce crack as well as damage to porcelain if used for a long time.

2) Injecting high pressure gas sand blasting or baking soda power for cleaning is pure physical impact to anilox roll surface, which existed disadvantages of uneven sand or powder particles and cannot into depth net-hole and cannot clean anilox roll with high number of lines; Direct high pressure injection is prone to subside leader of mesh roll after used for a long time.

3) Use ultrasonic cleaner is the combination function of chemistry and physics, micro water vacuole can come into net-hole directly and clean anilox roll with high number of lines; cleaning solution is neutral or partial weak base, impact of water vacuole produced by ultrasonic is very small, hence the damage to anilox roll is less.