Model: CHT

Power Supply: 400V 3Ph 50Hz (Customizable)

Application: Polymer removal

Workong Temperature: 420°C to 500°C

Heating: Electric heating

Temperature Control: Meter or PLC control

Control Accuracy: ±1°C

Color: Customizable

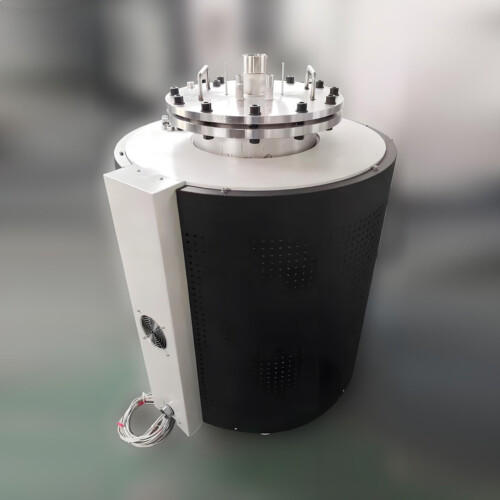

Carbonizing Furnace

Product Description

Carbonizing Furnace is used for cleaning polymers from a variety of metal parts, such as: moulds, extrusion dies, nozzles, extruders, hot runners, breaker plates.

► APPLICATIONS

- Moulds cleaning

- Extrusion dies cleaning

- Nozzles cleaning

- Breaker plates cleaning

► CONTROL

-

Precise PID temperature control

- SSR or SCR power controllers

-

Operating Temperature Range : 420°C to 500°C

-

Simple operation and complete safety protection function

-

Audible and visible alarm indicators

- Control Accuracy: ±1°C

- Available input power supply to your specifications

- Temperature recorder (optional)

- PLC with HMI(touch panel) (optional)

- Programmable temperature controllers (optional)

► SAFETY PROTECTION

- Separate excess temperature interlock to turn off heat on malfunction of main temperature controller

► FEATURES

- Control Panel – The digital PID Controller is mounted on the control panel . A standard “ON/OFF” indicating light was also provided, which is bright enough to be seen from a distance.

- Exterior – The exterior is constructed of carbon steel.

- Interior – The interior is constructed of stainless steel. It has heating elements installed at the side of the oven.

- Front loading or Top loading as per request

- Durable tubular heating elements

- All welded construction

- Adjustable exhaust outlet damper

- Durable loading shelf

- Insulated with alumina silicate fibre insulation

Notes: The unit could be entirely bespoke, we can design and tailor oven to the customer’s specification.